enEnglish

enEnglish

PROSOLV® SMCC

Silicified Microcrystalline Cellulose

Solving Tableting Challenges

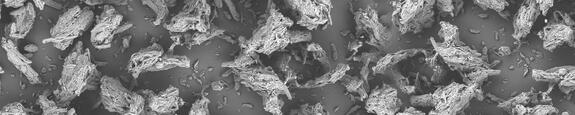

PROSOLV® SMCC, silicified microcrystalline cellulose, is a unique combination of microcrystalline cellulose (MCC) and colloidal silicon dioxide (CSD). A high functionality and multifunctional excipient, it requires less complex processing, has high inherent functionality, and passes that functionality on to the drug formulation.

PROSOLV® SMCC is unique in that it imparts both optimum compaction and superior flow to formulations. It also exhibits both brittle fracture and plastic deformation characteristics, leading to superior binding properties. The production process of PROSOLV® SMCC leads to homogenous and much finer CSD particle size distribution. This results in a five-fold specific surface area increase, as well as in a 30-50% compaction increase compared to traditional MCC. The increased surface area enables superior flow and increased compaction and results in improved content uniformity and stability in the formulation.

When used for direct compression, PROSOLV® SMCC can replace granulations, while significantly reducing the number of required excipients and use levels. PROSOLV® SMCC formulations produce distinctive, uniform, and cost effective tablets.

PROSOLV® SMCC is available in a number of different grades.

Benefits of Using PROSOLV® SMCC

Silicified Microcrystalline Cellulose, NF

Microcrystalline Cellulose, Ph.Eur., NF, JP, E 460(i) and Silica, Colloidal Anhydrous, Ph.Eur., E 551

Grade | Average Particle Size by Laser Diffraction (µm) | Bulk Density (g/mL) | Main Application |

PROSOLV® SMCC 50 | 65 | 0.25 – 0.37 | Designed for optimal compaction and decent flow. |

PROSOLV® SMCC 50 LD | 50 | 0.20 – 0.30 | SMCC grade with highest binding power. |

PROSOLV® SMCC 90 | 125 | 0.25 – 0.37 | For formulas where a balance of flow and compaction is required. |

PROSOLV® SMCC HD 90 | 125 | 0.38 – 0.50 | Optimized for flow, bulk density, and shortest disintegration times. |

PROSOLV® SMCC 90 LM | 125 | 0.27 – 0.39 | Equal quality to grade SMCC 90 but lower moisture content (< 3 %). |

Downloads

Brochure PROSOLV® SMCC

Over 25 years ago JRS PHARMA developed a new high

functionality excipient, , with enhanced PROSOLV SMCC®

properties for modern, high-speed tableting processes

Watch our Product Video PROSOLV® SMCC